CURRENT NEWS

What's making headlines

PROJECT HISTORY

What's Making headlines

Subsea Dredge Deployment Frame - August 2025

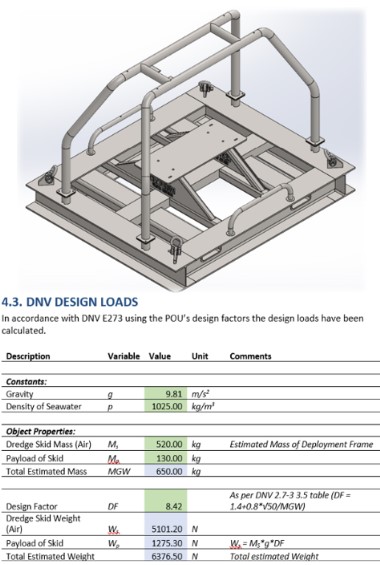

Project-managed the design and verification of the Subsea Dredge Deployment Frame as per the client scope requirements.

The frame design was in accordance with DNV 2.7-3 (Portable Offshore Units).

The project required designing the frame to DNV 2.7-3 so that it can deploy an 8" ventura dredge safely to the seabed. The lifting sling set was also designed in accordance with DNV and Australian standards.

Hariet Decommissioning - July 2025

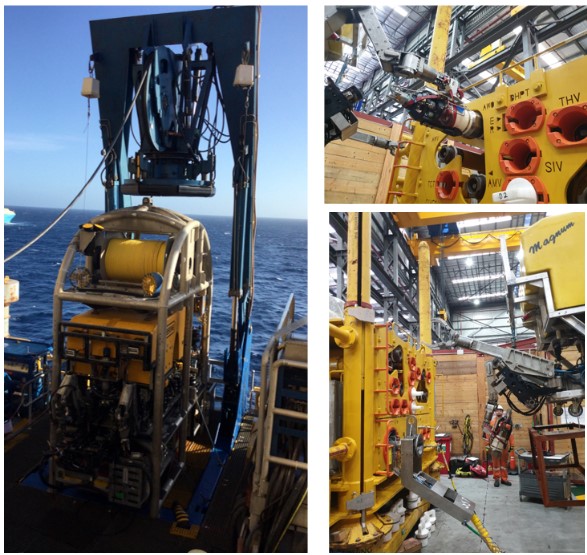

Project-managed the preparation of subsea equipment to assist with the decommissioning of the Hariet Field platform.

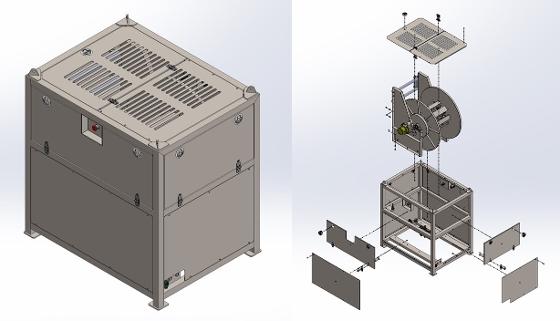

The equipment included a subsea deployment basket containing an 8" Ventura dredge controlled from the surface. A surface Hydraulic Power Unit with a hydraulic umbilical on the spooler unit.

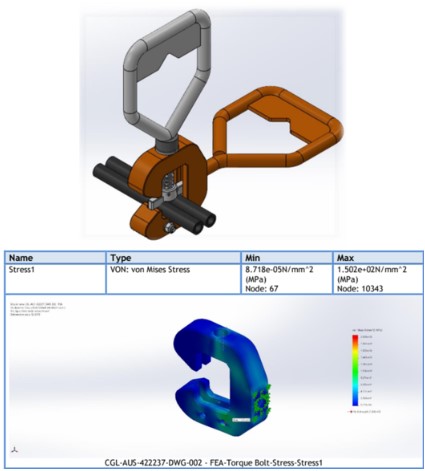

The project also required designing a hydraulic hose crimping tool to prevent residual hydraulic fluid from leaking when the hydraulic lines were cut. The hydraulic hose crimp tool was ROV-deployed, and the thread blade was screwed down to crush the hose without severing it to seal the hose off.

A schedule and documentation were prepared to support mobilisation, offshore operations, and maintenance for the project.

Crux Cement Remediation - June 2025

Project-managed the preparation of subsea equipment to break up excess concrete around the Crux Subsea Drilling Template.

The equipment included a subsea deployment basket containing 2x 8" ventura dredges controlled from the surface. A surface Hydraulic Power Unit with a hydraulic umbilical on the spooler unit. There was also a hydraulically operated grabber, and high-pressure water jetting units.

A schedule and documentation were prepared to assist in the mobilisation, offshore operations and maintenance for the project.

Unmanned Surface Vessel Mobilisation - April 2025

Project-managed the importation and mobilisation of a 24-metre Unmanned Surface Vessel from Norway to Perth, Australia. The Reach Subsea USV was contracted to complete a Subsea Gravimetric Survey of the Scarborough Field off the Northwest coast of Western Australia.

The USV was shipped from Norway aboard a heavy-lift vessel and unloaded into Fremantle Harbour before mobilisation commenced at AMC Henderson. The USV was re-flagged as Australian and upgraded for the start of the offshore project in November 2025.

The USV has a full work-class ROV system within the vessel that is deployed via a moonpool in the bottom of the vessel. The ROV was fitted with a specially designed Gravimetric Skid to transport sensor equipment from the USV to the 224 concrete pads on the seabed.

The development/establishment of a fully operational Remote Operation Centre in Bibra Lake to control all operational components of the USV. This included a Vessel Bridge, Navigators System, ROV Operational, Survey Operations and the specialised Gravimetric Survey controls.

Documentation for the mobilisation and offshore project execution was completed and approved by the end client. The documentation included Mobilisation Plans, Project Management Plan, Project Execution Plan, project schedules, task plans and engineering support.

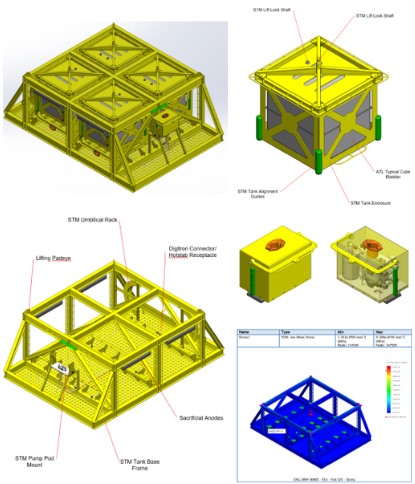

Pivotree Subsea Tank Module (STM) - September 2024

The STM mechanical design included the Subsea Tank Modules, Tank Subsea Gravity Structure, ROV and system interface components and the deployment/recovery guidance system. The main STMs are fully enclosed tanks capable of holding 4,000 litres; the 4 tanks can be replaced when depleted. Each tank is designed with an internal collapsible bladder that uses water pressure to assist in transferring fluid between the Tank Frame and the Subsea Pivotree. Each of the 4 Subsea Tanks are guided down into the interface base, which is secured onto the STM Gravity Structure. All hydraulic functions are connected via hydraulic zero-leak connectors.

A small pumping system was designed to transfer the fluids from each of the four tanks to the Subsea Pivotree as and when required. Volume sensors are fitted to communicate tank levels, enabling replacements before fluid depletion.

The design included structural design, material selection, finite element analysis, and calculations to confirm that the design is fit for purpose and meets the client's requirements. All subsea interfaces where design in accordance with ISO 13628-8 (Remotely Operated Vehicle interfaces on Subsea Production Systems).

All mechanical design elements where design in accordance with DNV 2.7-3 (Portable Offshore Units), API 17D (Specification for Subsea Wellhead and Tree Equipment).

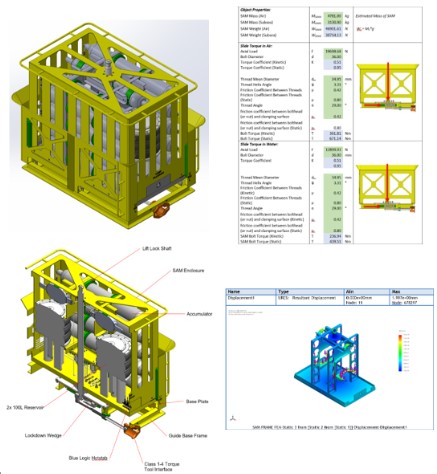

Pivotree Subsea Accumulator Module (SAM) - June 2024

The SAM mechanical design included the Subsea Accumulator Module enclosure, ROV and system interface components and the deployment/recovery guidance system. The main SAM enclosure is open to seawater, with the accumulator bank maintaining system pressure for all hydraulic functions of the Subsea Pivotree. The SAM enclosures are guided down into the interface base, which is secured onto the Subsea Tree. All hydraulic functions are connected via a series of hydraulic zero-leak connectors.

The design included structural design, material selection, finite element analysis, and calculations to confirm that the design is fit for purpose and meets the client's requirements. All subsea interfaces where design in accordance with ISO 13628-8 (Remotely Operated Vehicle interfaces on Subsea Production Systems).

All mechanical design elements where design in accordance with DNV 2.7-3 (Portable Offshore Units), API 17D (Specification for Subsea Wellhead and Tree Equipment).

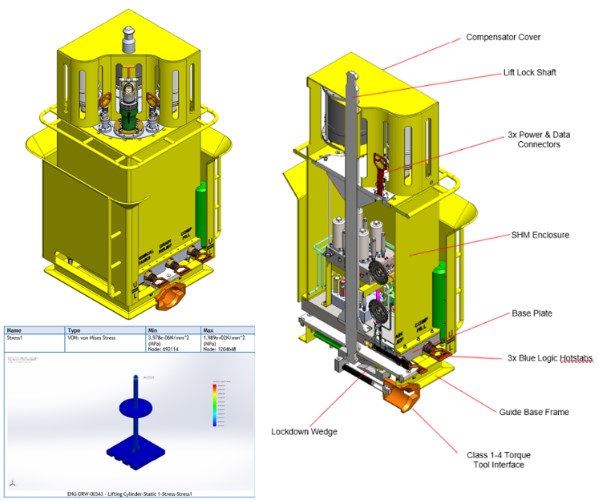

Pivotree Subsea Hydraulic Module (SHM) - March 2024

The SHM mechanical design included the Subsea Hydraulic Module enclosure, ROV and system interface components and the deployment/recovery guidance system. The main SHM enclosure is a sealed oil-filled system that controls all the hydraulic functions of the Subsea Pivotree. The SHM enclosures are guided down the interface base, which is secured onto the Subsea Tree. All hydraulic functions are connected via a series of hydraulic zero-leak connectors, whilst the electrical functions are connected using wet-mateable connectors.

The design included structural design, material selection, finite element analysis, and calculations to confirm that the design is fit for purpose and meets the client's requirements. All subsea interfaces where design in accordance with ISO 13628-8 (Remotely Operated Vehicle interfaces on Subsea Production Systems).

All mechanical design elements where design in accordance with DNV 2.7-3 (Portable Offshore Units), API 17D (Specification for Subsea Wellhead and Tree Equipment).

Stybarrow Abandonment ROV Operations - January 2024

Preparation of the documentation and conducting the ROV Operations onboard the MODU Transocean Endurance, as well as the ROV/Tooling SITs for the Stybarrow Abandonment Program.

All ROV Operations for the MODU ROV work scope, including well abandonment requirements. The work scope also included the inspection and preparation of all ROV tooling required for the offshore campaign.

Completion of the ROV Audit onboard the Mobile Offshore Drilling Unit, the Transocean Endurance, to IMCA Standards.

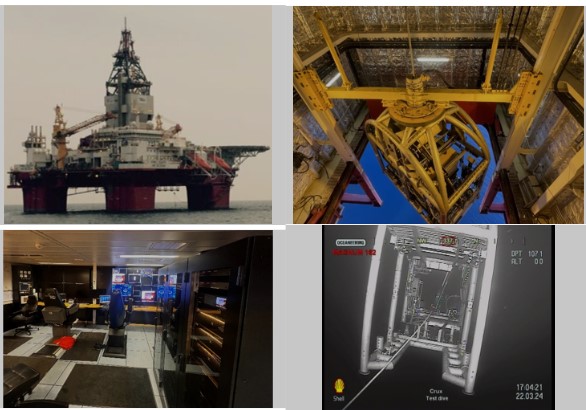

Crux Stage 1 ROV Drill Support - June 2023

Preparation of the documentation and conducting the ROV Operations onboard the MODU Transocean Equinox, as well as the ROV/Tooling SITs for the Crux Drilling Program.

All ROV Operations for the MODU ROV work scope, including batch drilling of five wells through the pre-installed template. The work scope also included the inspection and preparation of all ROV tooling required for the offshore campaign.

Completion of the two ROV Audits onboard the Mobile Offshore Drilling Unit, the Transocean Equinox, to IMCA Standards.

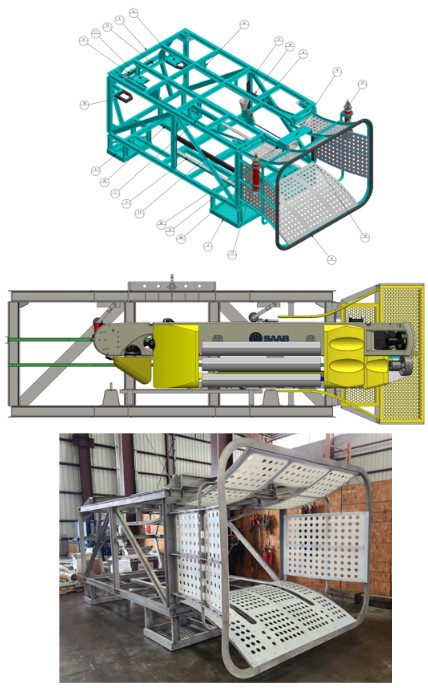

PXGEO - Ocean Bottom Node AUV Deployment Cage - December 2023

The deployment cage design was to transfer the AUV's from the vessel deck to the working depth. The cage could assist in guiding the AUV in and out of the cage. The guidance system enables the AUV to autonomously enter or exit the cage without interference.

The cage also had an automatic locking system that retains the AUV during deployment and recovery. To release itself, the AUV thrusts down, forcing the two paddles upwards, which mechanically release the locking mechanism.

The materials used were 316 stainless steel and HDPE.

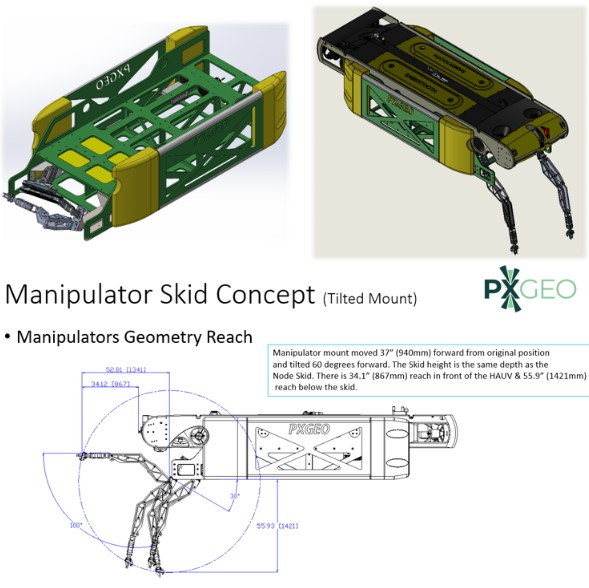

PXGEO - Ocean Bottom Node Rescue Skid for AUV - August 2023

Design and engineer a rescue skid that can be quickly attached to PXGEO's Sabre Seaeye Sabretooth AUV. The skid will be used if one of the AUVs becomes stranded and needs to be recovered to the Deployment Cage.

The skid has a small hydraulic power unit to control the 2 manipulators mounted at the front of the skid.

The design included the stress analysis of the full plastic frame and components.

MAG 224 ROV System Audit - July 2023

A full Remote Operated Vehicle audit was conducted on board the Ocean Apex during her Singapore dry dock.

The audit covered the ROV, the Launch & Recovery System, Tether Management System, Hydraulic Power Unit, Auxiliary Power Unit, Transformer Coffen, Control Van, Workshop and Store Container.

Thevenard Island Platform Decommissioning - May 2023

Preparation and testing of Diamond Wire Saw Systems for the removal of nine monopile/tripod platforms located off Thevenard Island.

Project Management of the offshore operation for the Diamond Wire scope of work.

Subsea Well Concept Proof of Design - Pivotree - March 2023

Assist Pivotree in conducting the modification to a Subsea Tree for the proof of concept of the Pivotree Subsea Well Design. The Subsea Tree was modified to remove the export flowline from the base of the tree and redirect it through a swivel joint at the top of the tree. The top of the swivel joint was the export flowline to the surface vessel.

The control system on the tree also had to be modified to hold an accumulator system to maintain hydraulic pressure, and the subsea control module had to be replaced with a Proserv model.

All modifications were complete, and testing was completed to achieve proof of concept from DNV.

Pyrenees Ph4 ROV Operations - Oct 2022

Preparation of the documentation and conducting the ROV Operations onboard the MODU Ocean Apex and Maersk Master as well as the ROV/Tooling SITs for both the Crosby 3H1 Water Shut Off and Stickle Workover Program.

All ROV Operations for both the MODU ROV workscope and the Pre-Rig work to be completed by the Maersk Master. Including the inspection and preparation of all the ROV tooling required for the offshore campaign.

Completion of the two ROV Audits onboard the Mobile Offshore Drilling Unit, the Ocean Apex, and the Maersk Master Vesselto IMCA Standards.

Adjustable Pipeline Spool Support Jacking System -June 2022

A 10 Tonne hydraulic cylinder system that is installed and operated via a Remote Operated Vehicle subsea to assist with the installation and maintenance of a subsea production pipeline in Australia.

The Spool Supports are adjustable by the Single-stage Hydraulic Cylinder Arrangement and Spacer Blocks to control the raising or lowering of the pipe spool. The Single-stage Hydraulic Cylinder are ROV installable and recovered once the Spool Support is locked in the correct position.

The system was designed, manufactured and tested in house and met all design scope requirements.

Multi-String Hot Tap Tooling - June 2021

Act as the Project Client and inspect and witness the System Integration Testing of a Multi-String Hot Tap Tool that will assist in the decommissioning of subsea wellheads.

The tool would clamp onto a decommissioned subsea wellhead and then drill a hole through the wellhead casing. As the tool drilled through the wellhead, it had to seal behind the hole. Some internal pressure can be monitored and safely released.

MMA was the client responsible for the offshore decommissioning operations in Thailand.

Aircraft Electric Belt Loader - May 2022

ISP designed an electric driven aircraft belt loader to suit an B737 similar to the current diesel version that the client has.

The unit can be towed to the aircraft but has a creep mode so it can be moved into position remotely or manually. The conveyor belt is electric driven that can be remotely controlled and emergency cut out switches at the top and bottom of the belt.

Safety guard rails to keep the luggage on the belt can be raised and lower via electric actuators, The guard rails also have extendable ends to close the gap between the aircraft hull and the end of the guard rails.

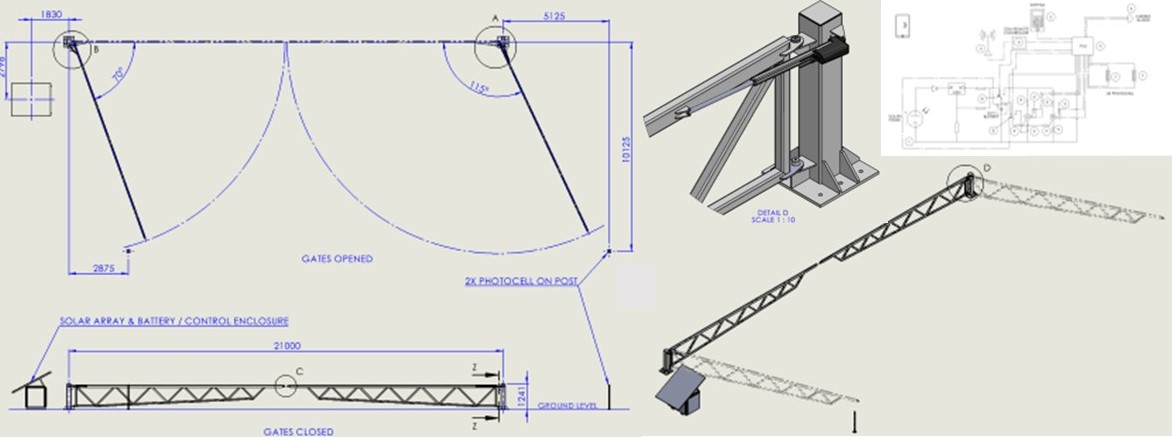

Mine Site Maintenance Facility Access Solar/Remote Gate -March 2022

The 21m wide gate span was design for a remote mine site maintenance facility. The gate could be opened and closed remotely from up to 100 different mobile phone codes, or operated manually. The system was completely free standing using a 390w Solar Module with 240 ah of battery storage.

The gates could open/close approximately 430 cycles per day for up to 4 day without the batteries needing recharging.

Basic Hydraulic Aircraft Belt Loader - December 2021

ISP designed a basic hydraulic driven aircraft belt loader to suit F100 & B717 aircraft.

The unit is towed to the aircraft and then manually pushed. The conveyor belt is hydraulic driven with an emergency stop at the top and bottom of the belt.

Manually deployed guard rails to keep the luggage on the belt can be raised or lowered.

TEK Ocean Spirit ROV Operations Review - October 2021

An elevation was conducted on the capabilities of the TEK-Ocean Spirit vessel and what ROV System would best suit the futured planned operational needs.

ROV Service Providers come in different shapes, sizes and capabilities. The reviewed looked at the industry requirements, ROV types, the competition within the market, a breakdown to determine the ROV Operations/Capability requirements.

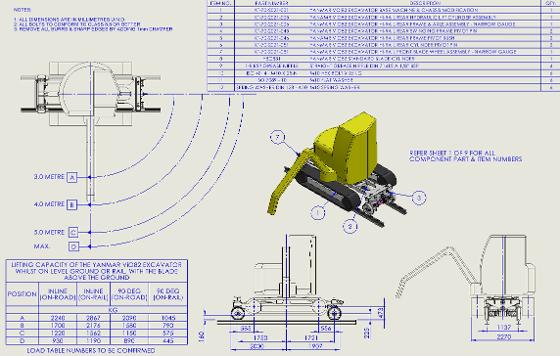

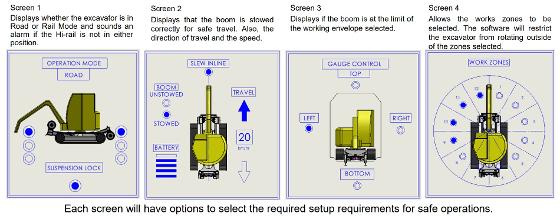

Yanmar Excavator Hi-Rail System - August 2021

The Yanmar Vio82 Excavator hi-rail system was dual gauge and self propelled. The system was designed to allow for over the side operations as well as inline operations, although at reduced capacity.

The hydraulics and electrical system where piggy backed onto the existing systems to minimise the amount of addition interfacing and controls required.

The system was designed in accordance with AS 7501, 7502 & 7508.

A specialised control system was developed to have safety interlock for travel and operational modes.

Hino 330 Series Hi-Rail Equipment Designed to AS7502 - June 2021

A narrow gauge Hi-Rail system was designed in accordance with AS 7502 to fit onto a Hino 330 series dual cab truck. The system was a Type 3 (Direct Drive) with a gross mass of 7.3 tonne.

The system is fully operational and met all test requirements.

Air Driven Cable Reeler - May 2022

ISP was contracted to design and detail an Air Driven Cable Reeler which could accommodate four different size cables and hoses. The design is similar to an existing unit that was already in the rental fleet.

The design of the Cable Reeler was reviewed against currently applicable codes, standards, and functional requirements. The design was carried out in accordance with DNV 2.7-3 Portable Offshore Units.

Four units have been manufactured and currently operational in the rental fleet.

Designing Portable Aircraft Stairs - March 2021

Design of six types of aircraft stairs for regional airports, as continued support for KTAS's ground service equipment.

Strategic Business Review for Total Marine Technology - July 2018

A review of Total Marine Technology's business development and governance structure was conducted to assist in understanding the companies strengthens and weaknesses and to highlight any gaps within the operations.

5 year Business Plan - December 2018

From the Strategic Business Review a 5-year Business Plan was developed for Total Marine Technology, a Strategic Planning session was also held with the senior management group to establish the companies Vision and Mission for the next 5 years.

© Copyright Innovative Solutions Plus